WIND:

WIND INTERMITTENCY IS EXAGGERATED – NREL study shows US wind potential is larger and more stable than previously thought with capacity factors of 65% available, see details HERE. Better even than Handleman Post predictions, that capacity factors of 50% can be achieved in large volume.

WIND INTERMITTENCY IS EXAGGERATED – NREL study shows US wind potential is larger and more stable than previously thought with capacity factors of 65% available, see details HERE. Better even than Handleman Post predictions, that capacity factors of 50% can be achieved in large volume.

![]() BEST US WIND SITES ARE BARELY TOUCHED – HERE – is a post showing where the best sites are why they are underutilized and how we can harvest much more wind at those sites.

BEST US WIND SITES ARE BARELY TOUCHED – HERE – is a post showing where the best sites are why they are underutilized and how we can harvest much more wind at those sites.

WIND TURBINE STATE OF THE ART – New wind turbine technology is further reducing the cost and intermittency of wind power – HERE

RENEWABLES IN GENERAL

– COST – The cost of Renewables Is Dropping Rapidly – HERE are some great graphs showing declining costs. Here is Lazards 2019 report showing that wind and solar are the least cost energy sources. HERE is Lazards 2018 report on the cost of generation showing solar and wind as the least cost sources. You can always get the most up to date version of this annual report by searching on ‘Lazard’s Levelized Cost’.

– GROWTH – The amount of renewable energy has been growing exponentially for decades. Here are some good graphics illustrate that growth.

– HERE is a link to videos of an entire course on renewable energy. The presenter is engaging making it fun and interesting.

STORAGE

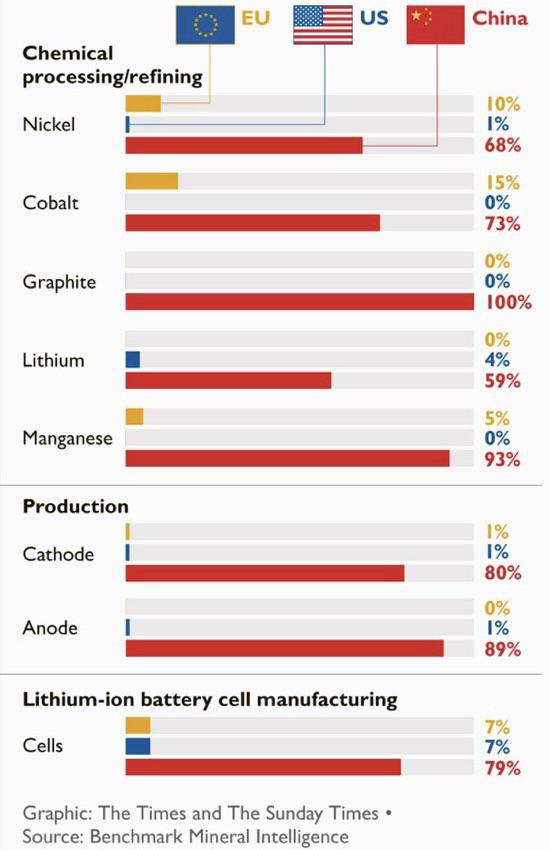

– Storage is vitally important for the future of renewable energy and many think that Lithium Ion batteries will play an important role if the cost can be brought down. Elon Musk predicts breaking the important $100 / kwhr barrier by 2025. This is in the same ballpark as predicted by Navigant and McKinsey prior to the Tesla announcement of the Gigafactory.

![]() – GIGAFACTORY A conservative bet for Tesla – HERE .

– GIGAFACTORY A conservative bet for Tesla – HERE .

– LITHIUM AVAILABILITY – And not to worry, there is plenty of Lithium – HERE .

![]() There has been much excitement over the Tesla Powerwall energy storage system. It is important but not for the reasons described in the press. My recent post post on the significance of Powerwall was picked up by The Energy Collective – HERE.

There has been much excitement over the Tesla Powerwall energy storage system. It is important but not for the reasons described in the press. My recent post post on the significance of Powerwall was picked up by The Energy Collective – HERE.

ELECTRIC VEHICLES INCLUDING ELON MUSK AND TESLA

– EV EMISSIONS – Electric Vehicles pollute less even when you take into account emissions from the generation source HERE And Tesla is the lowest emitter HERE.

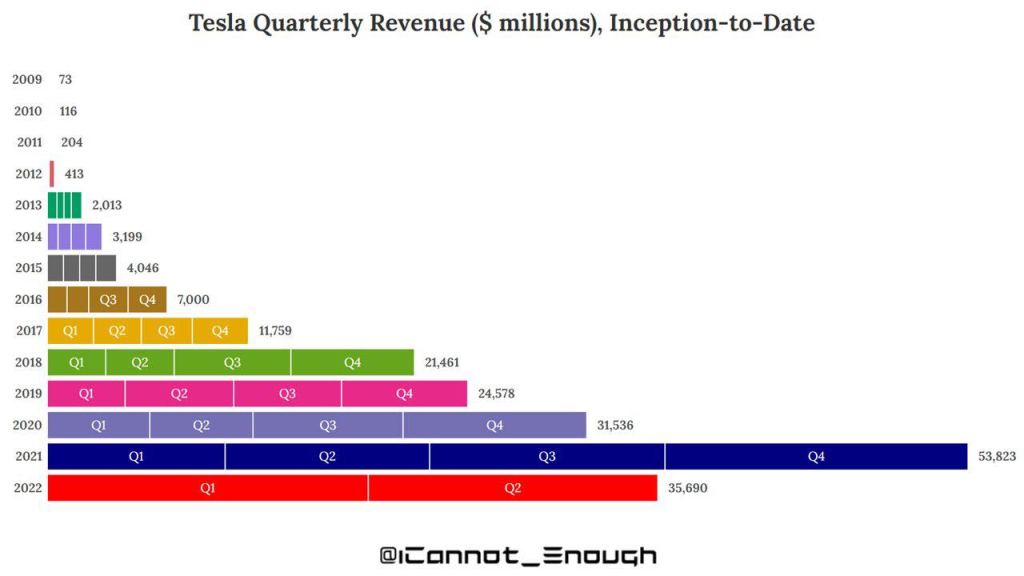

– TESLA IS REVOLUTIONARY – Tesla really is revolutionary. HERE

– BATTERY COSTS PLUMMET – EV batteries are the cost driver and they are coming down FAST – HERE – A 2021 graphic HERE

EVs FOR LOAD SHIFTING – EVs combined with Load Shifting use market forces to increase the value of wind power while reducing the cost of driving. – HERE

EVs FOR LOAD SHIFTING – EVs combined with Load Shifting use market forces to increase the value of wind power while reducing the cost of driving. – HERE

EV RANGE IS A NONISSUE – HERE ![]() .

.

The world according to Elon – Elon Musk on the Tesla road map from 2006. And now more from Elon on the derogatory Larry Hirsh article.

SOLAR

GIGA SCALE AND EFFICIENCY INCREASES POINT TO GRID PARITY – Multiple entrants in the <20% Efficient PV module space points to impending solar grid parity.

GIGA SCALE AND EFFICIENCY INCREASES POINT TO GRID PARITY – Multiple entrants in the <20% Efficient PV module space points to impending solar grid parity.

SOLAR LAND AREA – The Land area required for solar is relatively small in comparison to the overall human footprint.

EFFICIENCY

EFFICIENT LIGHTING – Incandescent bulbs are being phased out in favor of high efficiency lights. The most efficient is LED lighting which is dropping in price rapidly and is more efficient than CFLs – Here.

TRANSMISSION

Moving renewable energy from the best sites (eg Great Plains for wind, the Southwest for solar) to sites of highest demand such as the East Coast requires upgraded power transmission infrastructure

– EFFICIENT INTRACONTINENTAL POWER TRANSMISSION – Clean Line Energy HERE is developing HVDC transmission lines – HERE to do just that.

– LINKING THE THREE US GRIDS – The US is composed of three separate, independent electrical grids, by connecting the three grids Tres Amigas will make wider use of renewable energy possible.

BENEFITS OF AGGREGATION, A CASE STUDY – Texas’ grid expansion demonstrates a path towards higher wind penetration HERE . Completed transmission lines nearly eliminate curtailment.

BENEFITS OF AGGREGATION, A CASE STUDY – Texas’ grid expansion demonstrates a path towards higher wind penetration HERE . Completed transmission lines nearly eliminate curtailment.

TEACHER RESOURCES

These resources help you use renewable energy as a context to teach STEM.

Calculate the area required to power the earth with solar modules. This post discusses this and includes a spread sheet with the calculations.

This site has lots of data from a fixed and a tracking array. You can download the data or plot it on the site. If it doesn’t plot data for today then select an earlier date a couple of years earlier. It is an old site and the computers sometimes go down.

General Resources

BNEF report on the coming crash in oil.